Corrosion Protection Methods

Corrosion pervades our everyday life and has remained the undefeated villain in human history however we have learnt to understand the basic corrosion mechanisms and have even found ways to make corrosion work for humanity.

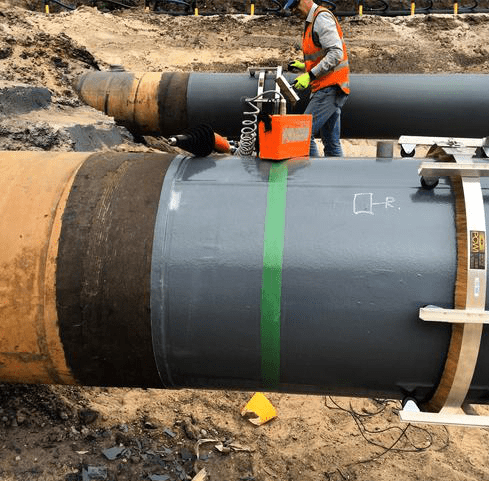

RemedyAP has experience in assessment, specification and inspection of corrosion and corrosion protection systems within the infrastructure and civil construction markets throughout Australia. With access to a network of industry professionals, RemedyAP have experience in consulting to industries with severe corrosion issues such as; Oil and Gas, Chemical Processing, and Wastewater Treatment Facilities.

Corrosion management

We have not found a way to stop corrosion, we have learnt to measure success in how long we can keep corrosion at a manageable level.

This involves understanding what durability requirements are needed for a structure in a certain environment.

Corrosion Control Methods

Our leadership identified a gap in the general construction market where corrosion is not properly addressed in mandatory codes and standards. This can leave specifiers, certifiers, building contractors and owners unprotected when things go wrong.

RemedyAP’s CorrAssure™ program has taken the durability lessons learned in heavy industry and packaged them into a set of systems and procedures for the general and civil construction industry to help protect everyone in the supply chain from the early onset of corrosion.

We provide quick response times – Contact us now!

Corrosion Prevention Methods

There are many achievements made in manufacturing where the corrosion protection outweighs the design life of a given product.

- The food and beverage industry have successfully preserved their products within metal can packaging which would otherwise corrode. What slows down the corrosion are thin film coatings to ensure that food remains sterile and protected from the elements and from the metal itself. These thin-film barrier coatings adhere to the interior of the can and provide a barrier to prevent interactions between food contents and the can.

- The automotive industry had made savings of $ 9.6 billion or 52 % annually in 1999 compared to 1975. This is due to various corrosion control methods including; material selection, drainage design, galvanic coupling, and coatings.

Corrosion Protection Services

Corrosion has won the battle against humanity, so far. However, we have found ways to trick corrosion into benefiting society. Some examples include;

- Batteries convert chemical energy into electrical charge by keeping all the elements of a corrosion cell except for a metallic pathway. The circuit is closed when the battery is installed between two terminals allowing the corrosion cell to activate.

- The manufacturing of hot water tanks has used cathodic protection to protect the coated steel tank from corroding by installing an anode, usually a rod of magnesium. The electro-negative potential between the steel tank and magnesium anode will force corrosion onto the anode where it sacrifices itself and protects the tank. The magnesium (the anode) corrodes instead of the steel tank (the cathode).

- Galvanizing of steel involves dipping steel in molten zinc or aluminium which creates a metallurgical bond between the steel and galvanizing material providing excellent adhesion. Additionally, the galvanizing material;

-

- i) Has a high affinity for corrosion however develops a passive oxide layer, quickly retarding any further corrosion reactions occurring. Therefore, it lays in wait for conditions to change.

- ii) If conditions change and corrosion is activated. the galvanizing material is anodic to the steel and will sacrifice itself in preference to the steel.