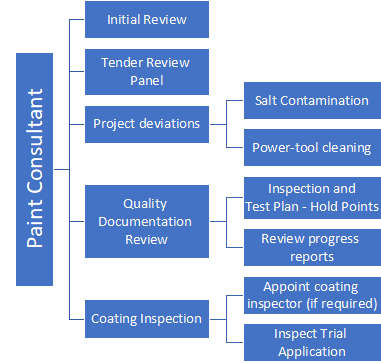

Paint Consultants

RemedyAP can be engaged to act as the paint consultant, or as certified inspector appointed by the Owner or any other party in the project team, and be responsible for:

Review of project documentation

Including:

- i) Condition assessment of new or existing structure

- ii) Assessment of corrosivity zone

- iii) Recommendation for project- specific specification

Assist the tender review panel in assessing the technical sections of the Applicator submissions.

Respond to technical queries raised in pre-start meetings and any other stage throughout the works.

Recommend Owner-initiated Hold points on the Inspection and Test Plan (ITP).

Review and approve Applicator ITPs and other quality documentation. This should occur at a frequency of:

- i) Pre-start – to determine the suitability of document templates related to this Specification,

- ii) Progress payment stages – to ensure documentation is being completed and submitted at each stage of Applicator payment claim, and,

- iii) Completion – to ensure final submission of documentation

Provide recommendation if an independent third-party coating inspector is needed to represent the Owner during inspection Hold points as described in the ITP.

Paint Assessment

Preliminary works include:

Defining the Owner's objectives, the asset lifecycle, and a Scope of Work.

Build a register for each condition assessment that includes

- A basic overview of facility, structure, and asset being inspected (what it is, materials of construction, age, current condition, and projected condition), utilizing available data.

- Informational security shall be maintained IAW Protective Data Security Standards.

Pre-inspection observations of assets and components are assessed through available data, site personnel, and expected conditions.

RemedyAP considers the following elements when developing an inspection plan:

- Concrete condition and assessment of required testing, including; core sampling, compressive strength, carbonation testing, and depth of cover.

- Metal condition and assessment, including; galvanizing thickness, corrosion survey, pit depth, and ultrasonic wall thickness.

Paint Testing

Coating condition and assessment of required testing, such as:

- i) Coatings containing hazardous pigments must be assessed IAW the revised AS4361.1 for lead, chromates, arsenic, and cadmium. Additional hazardous materials include coal tar and asbestos impregnated wraps.

- i) Coating durability tests are considered to provide an estimate of expected service life. These tests include adhesion, ultrasonic dry film thickness, blistering, defect mapping.

Insulation Inspection

Insulation inspection and fire-proofing inspection are critical given both conditions provide an annular for contaminants to collect and they both obscure the surface making identification of aggressive paint damage difficult to detect. RemedyAP have processes to provide risk-based inspection strategies and ensure you can remain protected from a corrosion related failure.

Thermal Imaging Inspection

Thermal imaging inspections are an important component of the effective operation of process equipment and piping systems. Where the temperature of the transported media differs from that of the surrounding air, thermal cameras can provide a vital role in inspection and maintenance efforts. By using thermographic systems, RemedyAP can quickly detect and localize defects to pipeline insulation, as well as leaks. Damage can emerge as a weakening of the cladding on the external insulation, as well as in leaks of heat energy, in addition to pipe breaks and losses of the transported medium.

Cost of Coating Inspection

The cost of services is generally recovered by the savings achieved through RemedyAP activities by:

- i) Preventing disorganised planning and poor documentation.

- ii) Providing sound project appraisal, desired quality outcomes, thorough inspections, and detailed reporting.

- iii) Protecting and Enhancing Client reputation for exemplary project delivery.